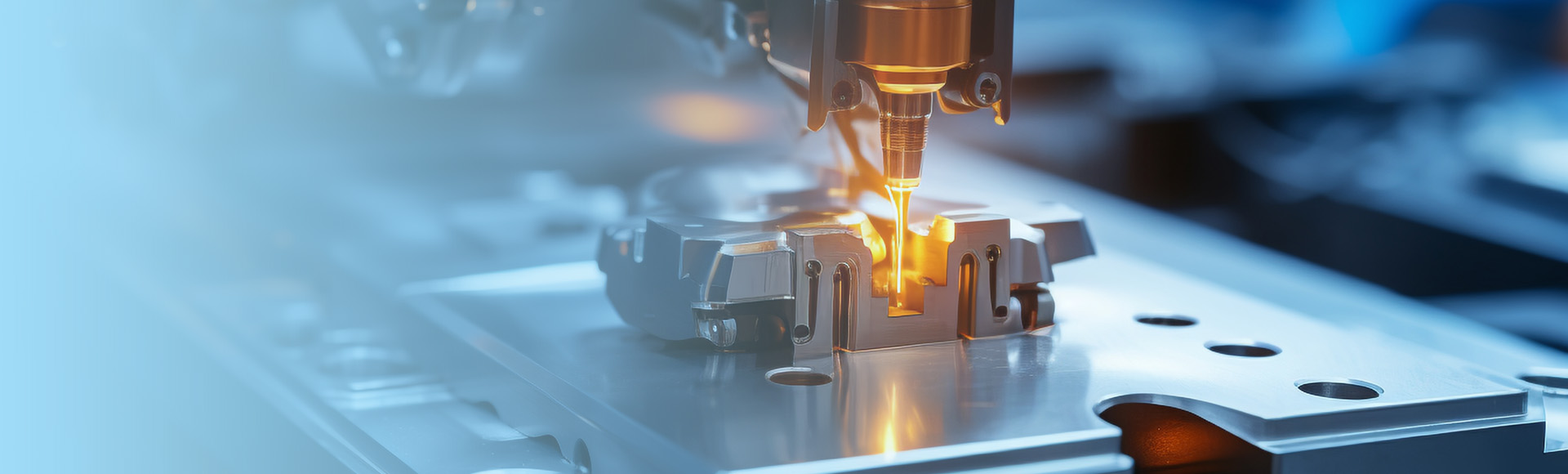

The function and setting method of pulse width in laser marking process

Laser marking is widely used in all walks of life, but the effect of many people is not ideal when operating, and the problem is often in the control of key parameters. Among them, the pulse width seems insignificant, but in fact, it affects the whole body. How does it affect the marking effect? And how to set it properly? Don't worry, here is a detailed interpretation for you, so that you can easily grasp the tricks.

Decide on the marking depth

The pulse width has a great influence on the marking depth. Simply put, the longer the pulse width, the longer the laser action on the surface of the material, the more energy the material absorbs, and the marking depth is naturally deeper. For example, when marking metal materials, if you want a deeper mark, you can appropriately increase the pulse width.

However, it should be noted that too long the pulse width may cause excessive thermal damage to the material and affect the material properties. Like normal metal, the pulse width is usually set at50-100.In nanoseconds, you can get a decent marking depth without damaging the material.

The marking accuracy is affected

Marking accuracy is also an important aspect of pulse width. A narrower pulse width can produce a finer laser beam, and the marked edges are clearer and sharper, resulting in higher accuracy. If the pulse width is too wide, the diffusion range of the laser beam on the surface of the material becomes larger, the edge of the marking pattern will become blurred, and the accuracy will be greatly reduced. When marking some high-precision electronic components, it is necessary to control the pulse width in a very narrow range, such as10 to 30Nanoseconds to ensure that the marking accuracy meets the requirements.

It's about marking speed

The pulse width is also closely related to the marking speed. Under normal circumstances, the narrower the pulse width, the more pulses can be emitted per unit time under the same laser energy, and the faster the marking speed. But if the pulse width is too narrow, each pulse carries insufficient energy and may not be able to form an effective marker on the surface of the material.

Therefore, when setting the pulse width, it is necessary to consider the material characteristics and marking speed requirements. For example, when large-area, low-precision marking of plastic materials, the pulse width can be appropriately increased, the number of pulses can be reduced, and the energy of a single pulse can be increased, so that the marking effect can be ensured and a certain marking speed can be maintained.

Adjustment setting method

Setting the pulse width is not a random adjustment, according to the type of material, marking requirements and other factors. Generally speaking, first consult the device manual to understand the range of pulse widths allowed by the device. Then, for different materials, the pulse width test is carried out in a small range.

Start with a narrow pulse width and gradually increase it, observing the marking effect, including depth, accuracy, speed, etc., until you find the most suitable pulse width value. In actual operation, it may also be necessary to combine other parameters such as laser power and frequency for repeated debugging to achieve the best marking effect.

Pulse width plays an important role in laser marking process, from marking depth, accuracy to speed are affected by it. Reasonable setting of pulse width is the key to achieve high quality and high efficiency laser marking. I hope that by understanding this knowledge, you can achieve better results in laser marking work.

Add WeChat

Add WeChat