Can laser cutting function realize the three-dimensional cutting of pipe and profile?

In the manufacturing industry, the processing needs of pipes and profiles are becoming more and more complex, and many people are curious about whether this common equipment, laser cutting machine, can solve the three-dimensional cutting of pipes and profiles. Today, Hevey Laser will tell you in detail, whether the laser cutting machine can achieve this seemingly difficult operation, and how to do it.

Equipment basis: multi-axis linkage is the key

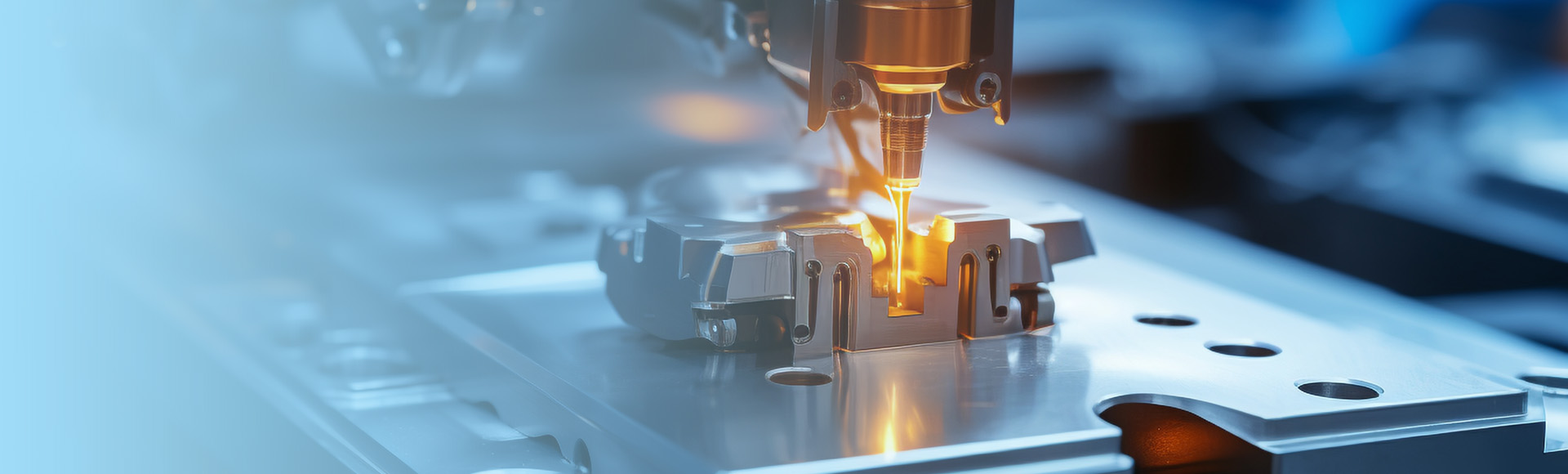

In order to realize the three-dimensional cutting of pipes and profiles, the laser cutting machine must have multi-axis linkage function. In general, the common two-dimensional laser cutting machine onlyX,YShaft, can only be cut on a flat surface. And three-dimensional cutting has to be at leastX,Y,ZAxis, plus the axis of rotation, likeAAxis,BAxes, etc.

With these axes working together, the laser cutting head can move flexibly in the space and cut at all angles of the pipe and profile. Just like when cutting a tube bend with a complex shape, the cutting head can move along the curved surface of the tube through the coordination of multiple

axes to complete accurate cutting.

Technical difficulties: The characteristics of the pipe pose challenges

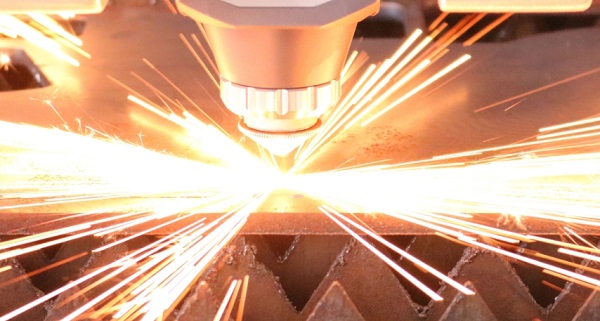

Pipes and profiles have their own characteristics, which bring many challenges to three-dimensional cutting. On the one hand, the circular or shaped cross-section of the pipe makes it difficult to maintain a consistent laser incidence Angle. If the Angle is not right, the cutting quality will be affected, such as uneven incision, hanging slag and other problems.

On the other hand, the inside of the pipe is hollow, and it is easy to produce thermal deformation when cutting. In order to solve these problems, we must rely on advanced laser control technology. For example, through the real-time monitoring system, according to the shape of the pipe and cutting progress, the laser power, pulse frequency and other parameters are automatically adjusted to ensure the stability of the cutting process.

Cutting process: Special process optimization effect

For the three-dimensional cutting of pipes and profiles, special cutting processes must be used. For example, when cutting thick wall pipes, high pressure gas is used to assist cutting in order to prevent blockage caused by the reflux of molten metal in the incision. The high-pressure gas quickly blows away the molten metal, making the cut smoother.

In addition, when cutting aluminum alloy profiles, taking into account the high reflectivity of aluminum alloy, the appropriate laser wavelength should be selected to reduce the loss of laser energy by reflection and improve the cutting efficiency.

Application case: Widely used in many fields

In practical applications, three-dimensional laser cutting pipes and profiles has played a role in many industries. In the field of automobile manufacturing, various special-shaped tubes on the frame can be quickly and accurately processed into the required shape through three-dimensional laser cutting, improving production efficiency and product quality.

In the architectural decoration industry, some aluminum alloy profiles with unique shapes use three-dimensional laser cutting to realize the processing of complex patterns and shapes, meeting the creative needs of designers.

Laser cutting machine can fully realize the three-dimensional cutting of pipes and profiles. As long as it has the multi-axis linkage function, overcome the technical difficulties, and adopt the appropriate cutting process, it can play an important role in many industries, providing efficient and accurate solutions for the processing of complex shapes of pipes and profiles.

Add WeChat

Add WeChat