Application areas: Suitable for electronic component spot welding, drag welding, sintering, heating, and automation of special welding processes on automated production lines

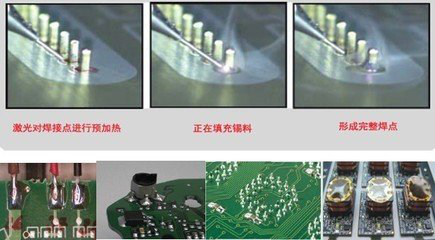

The Haiwei laser soldering machine system adopts advanced semiconductor lasers, high-precision motion control systems, and precise tin wire feeding mechanisms. Ensure the quality of every solder joint. Suitable for the automation of special welding processes such as spot welding, drag welding, sintering, heating, and automated production lines for electronic components. Due to its real-time high-precision control of the temperature of the welded object,

Especially suitable for high-precision soldering of high-temperature resistant components and thermal sensitive components around solder joints.

1. High soldering efficiency, especially suitable for mass production of multiple solder joints, can complete the processing of dozens of solder joints at once at high speed;

2. Excellent welding effect, full solder joints, and good consistency;

3. CCD imaging dynamic observation of welding process, laser CCD、 Red light three-point coaxial, avoiding complex debugging;

4. The coaxial CCD imaging system allows for clear and real-time presentation of solder joints in front of the eyes;

5. The tin feeding device can rotate 360 °;

6. Haiwei Laser's professional software control system.

model | HW-FWD60 | HW-FWD100 | HW-FWD150 |

Requirements of power supply | AC220V/±10%,50Hz | AC220V/±10%,50Hz | AC220V/±10%,50Hz |

equipment power | 1KW | 1.2KW | 1.5KW |

Laser power | 60W | 100W | 150W |

Wavelength | 980nm | 980nm | 980nm |

Work area | 300*200mm | ||

input/output | Input/Output I/O RS232 | ||

Localization way | Red diode indicator (option ccd) | ||

Feedback mode | Infrared feedback (optional) | ||

Cooling way | Separate cold | ||