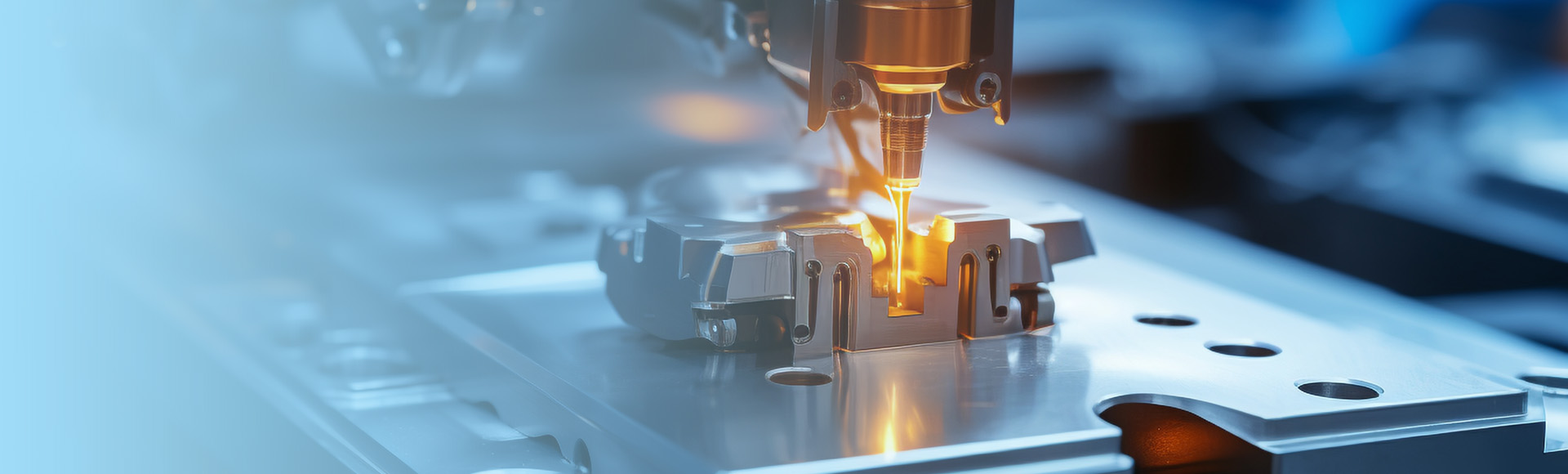

Is the maintenance cost of lithium battery laser welding machine high?

In the lithium battery production industry, lithium battery laser welding machine that is firmly occupiedCBits, which undertake critical welding tasks. But equipment, just like people, can be "faulty". Once the failure strikes, the maintenance cost instantly becomes the focus of the enterprise. Is the cost of maintenance outrageous, or is there a way to keep it within reasonable limits? Don't worry. Let's talk about it.

Core components determine the bulk of maintenance costs

The core components of the lithium battery laser welding machine, such as lasers, optical systems, control systems, etc., once there is a problem, the maintenance cost is often not low. As the core component of equipment, laser has high technical content and complex structure. If the pump source of the laser is damaged, the cost of replacing it is not low, if the optical resonator fails, the maintenance is not only technically difficult, but also high.

If the lenses in the optical system are dirty, worn or damaged, the replacement cost of high-precision lenses is also very high, and a piece may be thousands of yuan. If the circuit board of the control system is burned or the chip is damaged, the maintenance cost is also not low, because many times professional manufacturers are required to detect and repair.

Routine maintenance affects the frequency of maintenance

Whether daily maintenance is done well or not has a great impact on maintenance costs. If the company cleans the equipment regularly according to the equipment instructions, especially the optical lenses, to ensure that the laser transmission is not affected, it can reduce the failure caused by the lens problem. Regular inspection of the optical path system, so that the laser can accurately act on the welding point, but also to avoid welding quality problems caused by the optical path offset, reduce equipment maintenance.

If it is not maintained for a long time, the optical components are dirty, the mechanical parts are worn, the failure will occur frequently, and the maintenance cost will naturally increase significantly.

Maintenance channels around the maintenance price

The choice of maintenance channels is also critical. If you find the original equipment factory for maintenance, although the technology is guaranteed, the maintenance cost is usually higher, because the original factory has to charge a certain technical service fee, and the price of spare parts may be high.

If you find a third-party maintenance organization, the price may be relatively cheap, but the quality of maintenance is uneven. Therefore, enterprises have to choose qualified third-party maintenance institutions with good reputation, which can ensure the quality of maintenance and reduce the maintenance cost.

In addition, some minor faults, if the company's internal maintenance personnel have professional training, can repair themselves, you can save a lot of maintenance costs.

The maintenance cost of the lithium battery laser welding machine depends on many factors such as the status of the core components, the level of daily maintenance and the choice of maintenance channels. As long as enterprises do daily maintenance and reasonably choose maintenance channels, they can control maintenance costs to a certain extent, ensure the stable operation of equipment, and escort the production of lithium batteries.

Cost-effective, high stability lithium battery laser welding machine, preferred Hivi laser, 20 years of laser automation equipment industry experience, good equipment stability, basically no maintenance, there is also free on-site maintenance, after-sales timely, so that you have no worries.

Add WeChat

Add WeChat