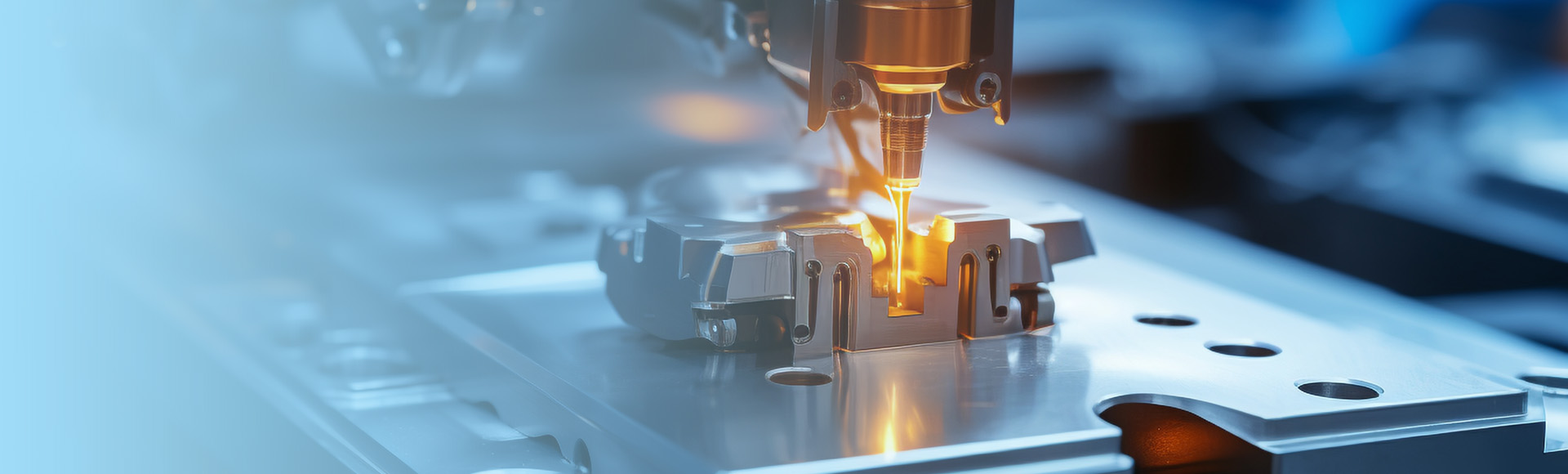

Optimization of welding process parameters of laser welding machine for lithium battery

In the production of lithium batteries, the role of lithium battery laser welding machine is becoming more and more important. However, if the welding process parameters are not adjusted, the welding quality cannot be guaranteed. Laser power, welding speed, pulse width, defocusing amount and other parameters have great influence on the welding effect. In order to do a good job of lithium battery welding, these parameters must be optimized in place. Here's how to do it.

Laser power: Precise control of heat input

Laser power is a critical parameter in welding process. If the power is too high, the heat absorbed at the weld is too much, it is easy to burn through, porosity, and these defects will also make the shell of the lithium battery seriously deformed, affecting the internal structure. If the power is too low, it will lead to weak welding and insufficient weld strength.

For example, when welding a thin lithium battery electrode sheet, we set the laser power of the lithium battery laser welding machine in a relatively low range, about 1000-1500W, which can ensure that the electrode sheet is effectively welded, and will not be damaged by overheating. And welding a slightly thicker lithium battery shell, the power may be increased to 2000-6000W.

Welding speed: Balance heat distribution and efficiency

Welding speed also has great influence on welding quality. The speed of the lithium battery laser welding machine is too slow, and the heat accumulates in a large amount in the local area, which is easy to melt the material excessively and increase the risk of deformation. If the speed is too fast, the laser energy can not be fully absorbed by the material, and the weld will appear virtual welding and incomplete welding.

Pulse width: Fine control of energy release

The pulse width determines the length of time the laser pulse acts on the material. The right pulse width allows the heat release of each welding to be just right. For lithium battery welding, the narrow pulse width is very useful when welding high-reflectivity metal materials, such as welding copper electrodes, the narrow pulse width can reduce reflection, so that the laser energy is better absorbed by the material, and improve the welding quality. In general, welding lithium battery electrodes such as fine parts, the pulse width can be set in0.5-2In milliseconds.

Defocusing amount: guarantee welding stability

Defocus refers to the position of the laser focus relative to the surface of the solder. Positive defocusing can make the spot larger and reduce the energy density, which is suitable for welding thin materials in lithium battery laser welding machine to avoid burning through. Negative defocusing makes the spot smaller and the energy density increase, which is suitable for welding thick materials. In lithium battery welding, we need to accurately adjust the defocus amount for different thickness materials.

The optimization of welding process parameters of lithium battery laser welding machine is a process of comprehensive consideration and repeated trials. Only the laser power, welding speed, pulse width, defocus and other parameters are adjusted to the appropriate state, in order to ensure the welding quality of lithium batteries, improve product performance and production efficiency, to meet the growing market demand.

Add WeChat

Add WeChat