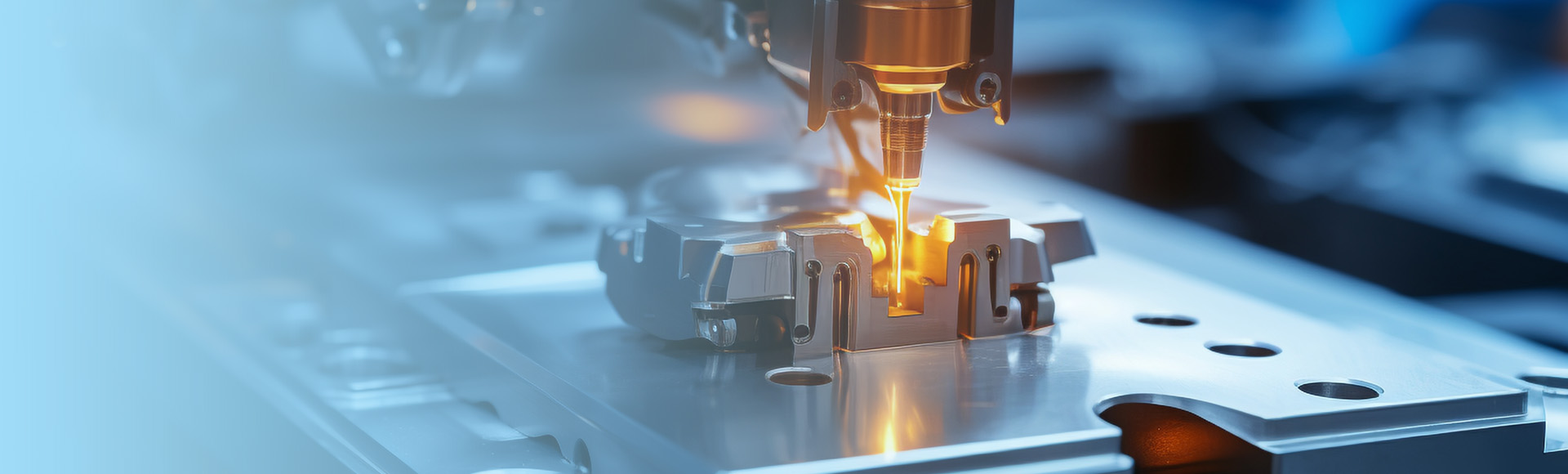

Lithium battery laser welding machine company: laser equipment automatic welding process

Lithium battery production is highly competitive today, and to stand out in the market, improving the welding process is crucial. The disadvantages of traditional manual welding are gradually apparent, and the automatic welding process is rising along the trend. What is the automatic welding process of lithium battery laser welding machine? What's so special about it? Next, the lithium battery laser welding machine company Haiwei Laser gives you an in-depth introduction to see how it changes the industry pattern.

Automatic welding system composition

A complete set of automatic welding system of lithium battery laser welding machine is mainly composed of mechanical motion mechanism, control system, laser generating device and detection feedback device. The mechanical motion mechanism is like a human limb, responsible for accurately moving the welding part or welding head, and the common high-precision robotic arm and linear guide rail can achieve micron level positioning accuracy.

The control system is like the brain, directing the various components to work together, and can precisely control the welding speed, path and time according to the preset program. The laser generator provides the high energy laser beam needed for welding, and its stability and energy output accuracy directly affect the welding quality. The detection feedback device is like an eye, which monitors the welding process in real time, and can feed back to the control system for adjustment once an anomaly is found.

Advantages of automatic welding process

Compared with the traditional manual welding, the automatic welding process has obvious advantages. The first is extremely high welding accuracy and consistency. During manual welding, the weld quality is uneven due to the influence of workers' status and technical level. The automatic welding system can accurately control the welding parameters to ensure that the quality of each solder joint is the same, which greatly reduces the defective rate. Second, production efficiency has been greatly improved.

Automation equipment is tireless, can24Hours of continuous operation, and the welding speed is fast, several times or even tens of times that of manual welding. Moreover, automatic welding reduces manual operation, reduces labor costs, and also reduces safety risks caused by human factors.

Key technology of automatic welding process

To achieve efficient automatic welding, there are several key technologies. The first is the path planning technology, through the software to accurately plan the welding path, to ensure that the laser beam can be welded according to the optimal route, to avoid missed welding and repeated welding. The second is the adaptive control technology, the system can automatically adjust the laser power, welding speed, etc. according to the temperature, current and other parameters detected in real time during the welding process to adapt to different welding conditions.

For example, when welding lithium battery electrodes of different thicknesses, the parameters can be automatically adjusted to ensure welding quality. The third is visual recognition technology, using cameras and other equipment to obtain real-time image information of welding parts, quickly identify welding positions and defects, and provide accurate data for the control system.

The automatic welding process of lithium battery laser welding machine has huge advantages in improving production efficiency and ensuring product quality, and is an important means for lithium battery manufacturers to enhance their competitiveness, which is worth in-depth understanding and active application.

High cost performance lithium battery laser welding machine, preferred lithium battery laser welding machine company, 20 years of laser automation equipment industry experience, to provide a variety of new energy lithium battery laser processing solutions.

Add WeChat

Add WeChat