Non standard automated laser equipment has emerged to meet special processing requirements.

Learn more >

The structural characteristics of non-ferrous metals copper and aluminum are unique, especially in the welding operation in the joint area, which requires extremely high welding process standards. Traditional welding often leads to uneven weld seams, insufficient bonding strength, a wide range of thermal effects, and subsequently causes problems such as decreased material conductivity and corrosion resistance, which is a major challenge in the industry.

Learn more >

In the field of medical device manufacturing, especially in the production process involving microfluidic devices and precision diagnostic equipment, there are extremely strict standards for the cleanliness, environmental friendliness, and accuracy of welding processes.

Learn more >

With the rapid development of the eyewear industry and the diversification of consumer aesthetic needs, the materials used in eyeglass frames are becoming increasingly diverse

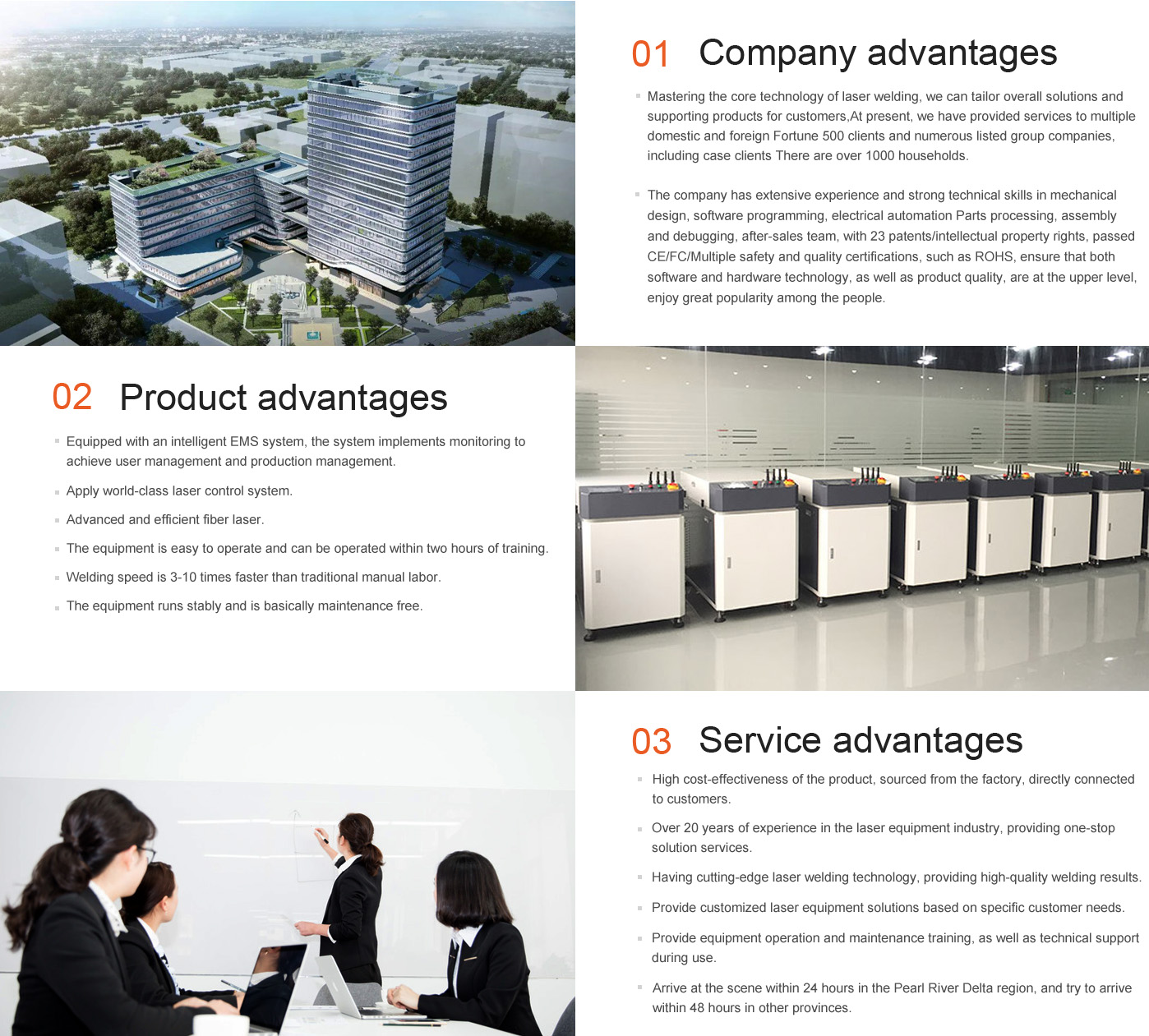

Learn more >Shenzhen Haiwei Laser Technology Co., Ltd. is an innovative enterprise with over 17 years of professional experience in the field of laser applications. It integrates research and development, production, sales, and service, and is committed to providing customers with professional automated laser processing solutions. As a national high-tech enterprise, we have obtained more than 50 patents and intellectual property rights, which are widely used in industries such as new energy, 3C, precision hardware, automotive parts, medical equipment, military aviation, precision electronic components, jewelry, etc., and have received widespread praise.

On March 11, 2025, in the activities held by Shenzhen High-tech Enterprise Collaborative Innovation Promotion Association (Shenzhen High Promotion Association), Shenzhen Haiwei Laser Technology Co., Ltd. won the \"Scientific and Technological Innovation Award\" with its excellent performance in the field of laser technology. Shenzhen High Promotion Association as a national small and medium-sized enterprises public service demonstration platform, the establishment of the award to commend the innovation of outstanding enterprises in the field of high-tech, Hiwei laser stands out, highlighting its own strong innovation strength and technical heritage.

Recently, Shenzhen Haiwei Laser Technology Co., Ltd. ushered in an exciting good news-Recognized by Shenzhen SME Service Bureau as\"Specialized in special new small and medium-sized enterprises\"This honor not only reflects the company\'s excellent performance in technological innovation and market competitiveness, but also injects new impetus into the company\'s future development.

On a sunny afternoon, when the warm sun filled every corner of the campus, HiVI Laser joined hands with science and technology education into the campus of Shenzhen Huayi Experimental School. This event aims to open a door to the high-tech world for children, let them feel the charm of laser technology up close, and stimulate their interest and curiosity in science.

In the production of lithium batteries, the role of lithium battery laser welding machine is becoming more and more important. However, if the welding process parameters are not adjusted, the welding quality cannot be guaranteed. Laser power, welding speed, pulse width, defocusing amount and other parameters have great influence on the welding effect. In order to do a good job of lithium battery welding, these parameters must be optimized in place. Here\'s how to do it.

In the production process of lithium batteries, welding deformation is a headache. Welding deformation will not only affect the appearance of the battery, but also cause damage to the internal structure of the battery, which will affect the performance and safety of the battery. As a laser welding machine manufacturer in the field of laser automation equipment for 20 years, Hewei Laser today will give you a good talk about how to reduce the welding deformation of lithium battery laser welding machine.

Lithium battery production is highly competitive today, and to stand out in the market, improving the welding process is crucial. The disadvantages of traditional manual welding are gradually apparent, and the automatic welding process is rising along the trend. What is the automatic welding process of lithium battery laser welding machine? What\'s so special about it? Next, the lithium battery laser welding machine company Haiwei Laser gives you an in-depth introduction to see how it changes the industry pattern.

Competition in the lithium battery industry is fierce, and companies are racking their brains to cut costs and improve efficiency. Lithium battery laser welding machine occupies a key position in the production process, but many companies are entangled: improve its utilization rate, in the end can really reduce costs? Today, we will analyze this problem from many aspects such as equipment depreciation, energy consumption, manpower and maintenance, and give you a clear answer.

In the lithium battery production industry, lithium battery laser welding machine that is firmly occupiedCBits, which undertake critical welding tasks. But equipment, just like people, can be \"faulty\". Once the failure strikes, the maintenance cost instantly becomes the focus of the enterprise. Is the cost of maintenance outrageous, or is there a way to keep it within reasonable limits? Don\'t worry. Let\'s talk about it.

In the use of laser marking machines, precise control of marking depth is crucial, as it directly affects whether the product marking effect can meet the requirements. Whether for clear identification of product information or achieving specific process effects, understanding the precise control range of marking depth is key.

During the use of a laser marking machine, many parameters will affect the marking effect, among which the repetition rate is a crucial one. Whether it is the pursuit of efficient production in the manufacturing industry or the strict requirements for product labeling precision, repetition frequency plays a crucial role. How does it affect the marking speed and quality? Next, we will provide a professional analysis for everyone.

Laser marking is widely used in all walks of life, but the effect of many people is not ideal when operating, and the problem is often in the control of key parameters. Among them, the pulse width seems insignificant, but in fact, it affects the whole body. How does it affect the marking effect? And how to set it properly? Don\'t worry, here is a detailed interpretation for you, so that you can easily grasp the tricks.

In the actual operation of the laser marking machine, we will consider the influence of various factors on the marking effect, of which the role of the laser wavelength can not be underestimated. Today, laser marking machine manufacturer Hewei Laser combined with 20 years of laser equipment experience, to tell you how the wavelength of the laser marking machine is about the marking effect.

The heat affected zone of laser cutting machines has always been a key issue of concern. After all, if the heat affected area is too large, the performance and cutting accuracy of the material will be affected. So, many people are curious whether laser cutting machines can monitor and control the heat affected area in real-time during the cutting process? Next, we will provide professional answers for everyone.

In industrial processing, efficiency is very important. For a long time, everyone has been exploring how to do the cutting task faster and better. The emergence of laser cutting machine has undoubtedly brought new vitality to the processing industry. Next, Hervey Laser will professionally share with you how much processing time the laser cutting machine can reduce compared with the traditional cutting equipment.

In the manufacturing industry, the processing needs of pipes and profiles are becoming more and more complex, and many people are curious about whether this common equipment, laser cutting machine, can solve the three-dimensional cutting of pipes and profiles. Today, Hevey Laser will tell you in detail, whether the laser cutting machine can achieve this seemingly difficult operation, and how to do it.

Add WeChat

Add WeChat